Turning Ideas Into Functional Ergonomic Grips

Design

From initial concept and prototyping to final production, our in house team of designers can design the ideal grip for your application.

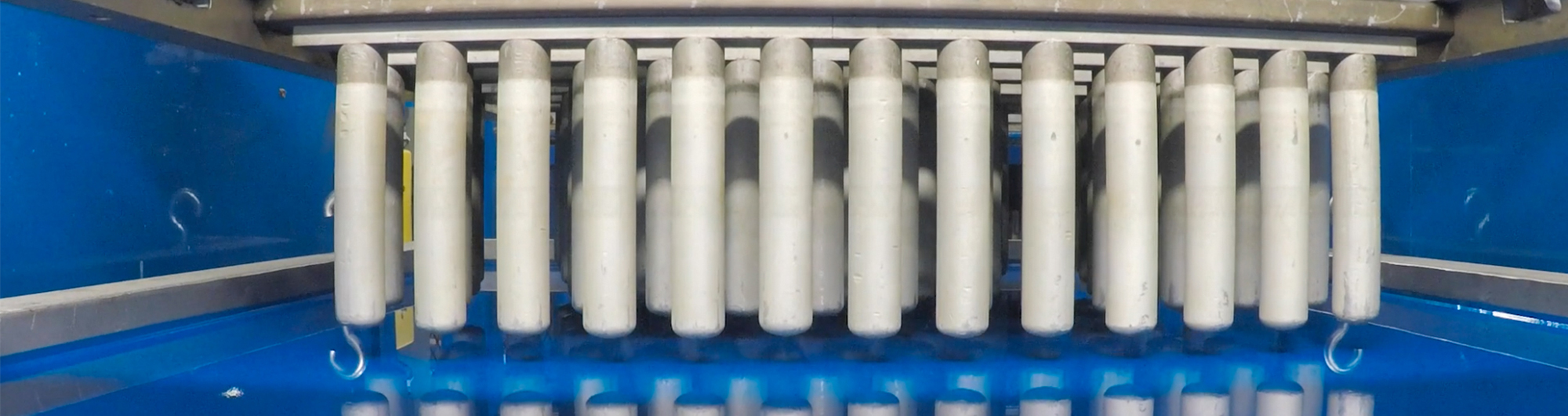

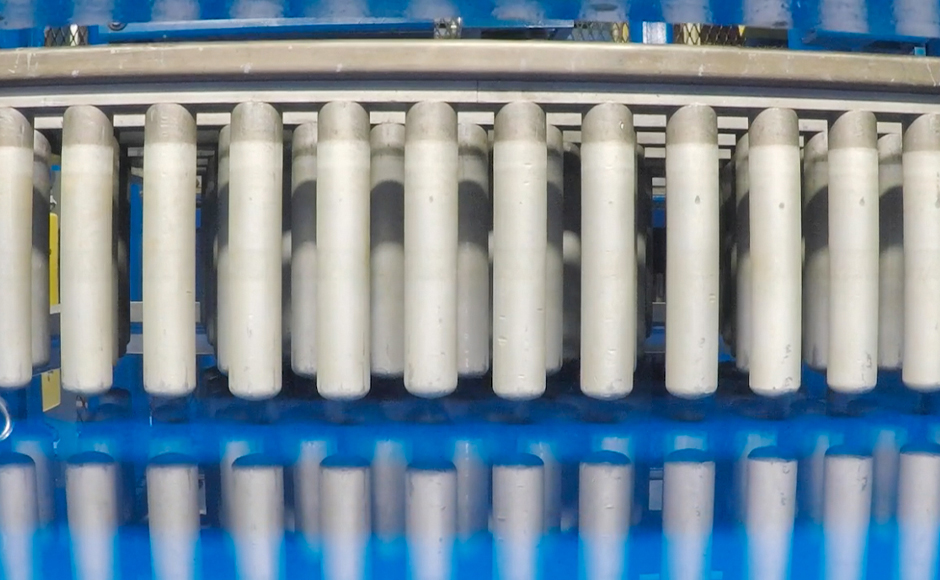

Dip Molding

With over 70 years of experience, Gripworks' dip molding, double dipping and material formulation capabilities are second to none.

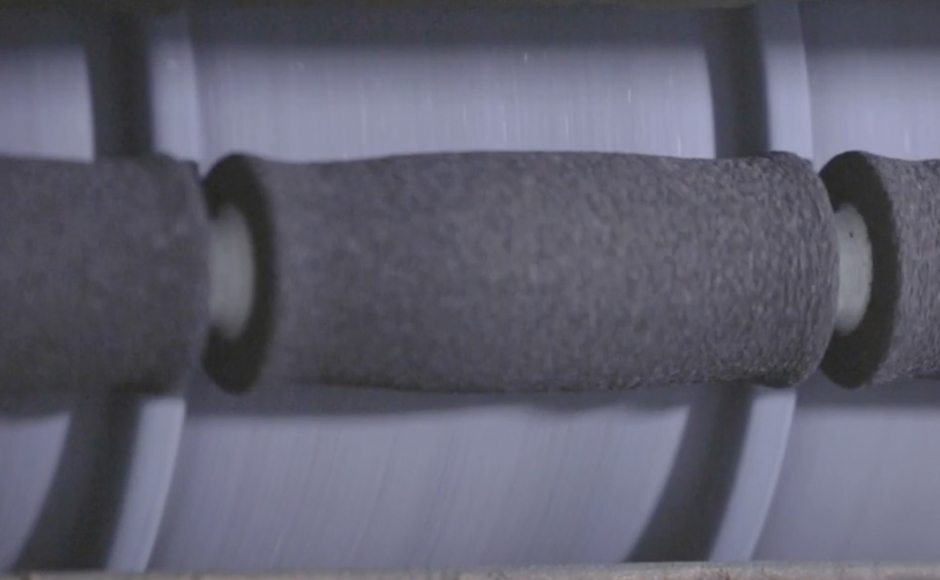

Injection Molding

Gripworks has injection molding capabilities on three continents with the ability to manufacture both 1-shot and 2-shot grips.

Notes

- GripWorks is a manufacturer of grips directly supplying other Original Equipment Manufacturers (OEM). Orders for non-stock items typically require a production run with a minimum requirement of 2,500 to 5,000 grips.

- For smaller quanity applications, we offer a selection of stock vinyl and foam grips and tubes that are available in our online store.

- GripWorks is pleased to offer samples for fit and function testing. In some cases, a refundable charge may apply.